Client

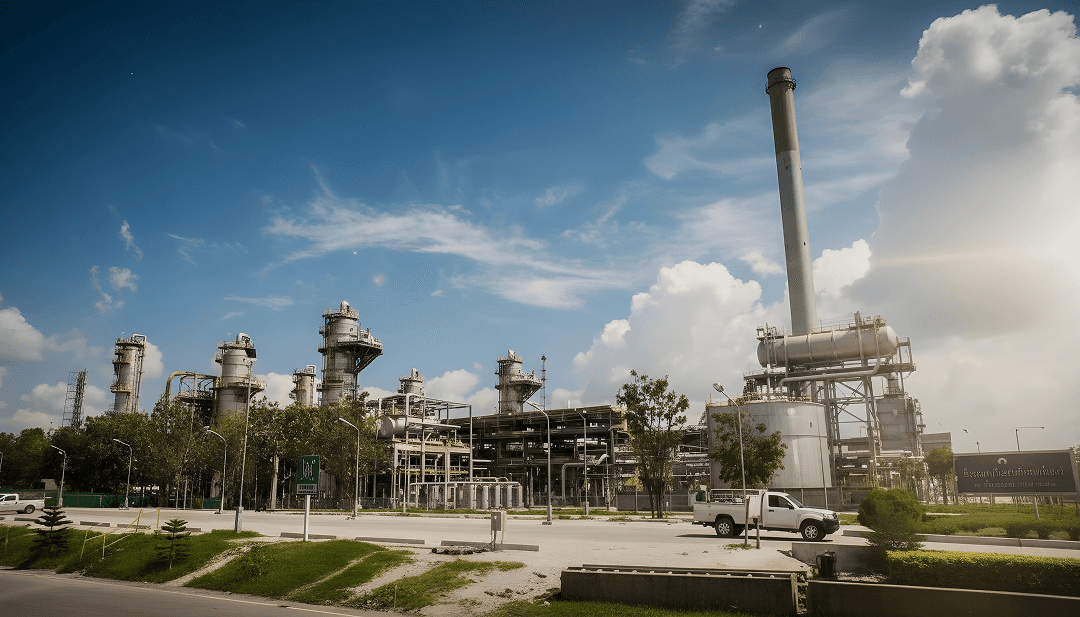

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Monitoring hazardous gas levels at a Gas refinery in Thailand

PTT

Environment

The Results

PTT Gas refinery, Rayong is now empowered to examine a real-time reading of the gaseous levels present in the air. The workers and residents in and around the Gas refinery can now rest assured that the monitoring of the harmful gases is in process. With the help of MUI-Robotics’ Environmental Monitoring solution, PTT can now enable smart alerts (email & SMS alerts) to be notified of any leakage, concentration of gas, or particulate matter. This ensures timely notification, and the Hazard team can adopt appropriate corrective actions that best suit the need.

Team at PTT

Team at PTT

Team at PTT

MUI-Robotic’s environmental monitoring solution ability in monitoring the environmental conditions has been exceptional. PTT health and safety department highlighted that the data analytics platform & the real-time data feed is helpful in monitoring the air quality.

MUI-Robotic’s environmental monitoring solution ability in monitoring the environmental conditions has been exceptional. PTT health and safety department highlighted that the data analytics platform & the real-time data feed is helpful in monitoring the air quality.

Next Case Study

Products

Get in touch

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Monitoring hazardous gas levels at a Gas refinery in Thailand

PTT

Environment

The Results

PTT Gas refinery, Rayong is now empowered to examine a real-time reading of the gaseous levels present in the air. The workers and residents in and around the Gas refinery can now rest assured that the monitoring of the harmful gases is in process. With the help of MUI-Robotics’ Environmental Monitoring solution, PTT can now enable smart alerts (email & SMS alerts) to be notified of any leakage, concentration of gas, or particulate matter. This ensures timely notification, and the Hazard team can adopt appropriate corrective actions that best suit the need.

Team at PTT

Team at PTT

Team at PTT

MUI-Robotic’s environmental monitoring solution ability in monitoring the environmental conditions has been exceptional. PTT health and safety department highlighted that the data analytics platform & the real-time data feed is helpful in monitoring the air quality.

MUI-Robotic’s environmental monitoring solution ability in monitoring the environmental conditions has been exceptional. PTT health and safety department highlighted that the data analytics platform & the real-time data feed is helpful in monitoring the air quality.

Next Case Study

Products

Get in touch

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Client

PTT Public Company Limited or simply PTT (Thai: ปตท จำกัด (มหาชน)) is a Thai state-owned, SET-listed oil and gas company. Formerly known as the Petroleum Authority of Thailand, it owns extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals throughout the kingdom. The PTT Gas refinery in the Rayong province hosts a number of workers every day. It is important to monitor the hazardous gaseous levels that could pose a threat to their health.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Challenge

PTT Gas refinery was due for an upgrade for air monitoring system that notified them of hazardous gases and particulate matters in the air around their Gas refinery. To optimize the safety and security of the workers in the PTT Oil refinery, detecting odours and harmful gases like nitrogen oxides (NO2), carbon monoxide (CO2), hydrogen sulfide (H2S), sulfur dioxide (SO2), and other Particulate Matters like PM2.5, PM10 were necessary. In times of leakage or when the gaseous levels cross the threshold level, PTT did not have an easy means to procure the information and help warn the workers and the residents of the Rayong province.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Solution

MUI-Robotics offered its sustainable and patented, MUI-Station, to the Rayong branch PTT Gas refinery. It was a perfect solution as MUI-Robotics’ expertise lies in detecting and monitoring such harmful gases as mentioned above. MUI-Station can help PTT to get a smart, affordable, and accurate reading of the gaseous levels in the air on a real-time basis. It can even be done remotely through a wide range of network connectivity options. This function is designed to help in notifying the authorities, workers, and residents in and around the Gas refinery in case of any leakage or any presence of harmful substances in the air.

Monitoring hazardous gas levels at a Gas refinery in Thailand

PTT

Environment

The Results

PTT Gas refinery, Rayong is now empowered to examine a real-time reading of the gaseous levels present in the air. The workers and residents in and around the Gas refinery can now rest assured that the monitoring of the harmful gases is in process. With the help of MUI-Robotics’ Environmental Monitoring solution, PTT can now enable smart alerts (email & SMS alerts) to be notified of any leakage, concentration of gas, or particulate matter. This ensures timely notification, and the Hazard team can adopt appropriate corrective actions that best suit the need.

Team at PTT

Team at PTT

Team at PTT

MUI-Robotic’s environmental monitoring solution ability in monitoring the environmental conditions has been exceptional. PTT health and safety department highlighted that the data analytics platform & the real-time data feed is helpful in monitoring the air quality.

MUI-Robotic’s environmental monitoring solution ability in monitoring the environmental conditions has been exceptional. PTT health and safety department highlighted that the data analytics platform & the real-time data feed is helpful in monitoring the air quality.